Services

Our Services

Transform downtime into productive time

Reach out to discuss how our proactive maintenance and precise repairs can elevate your efficiency.

Heavy duty industries

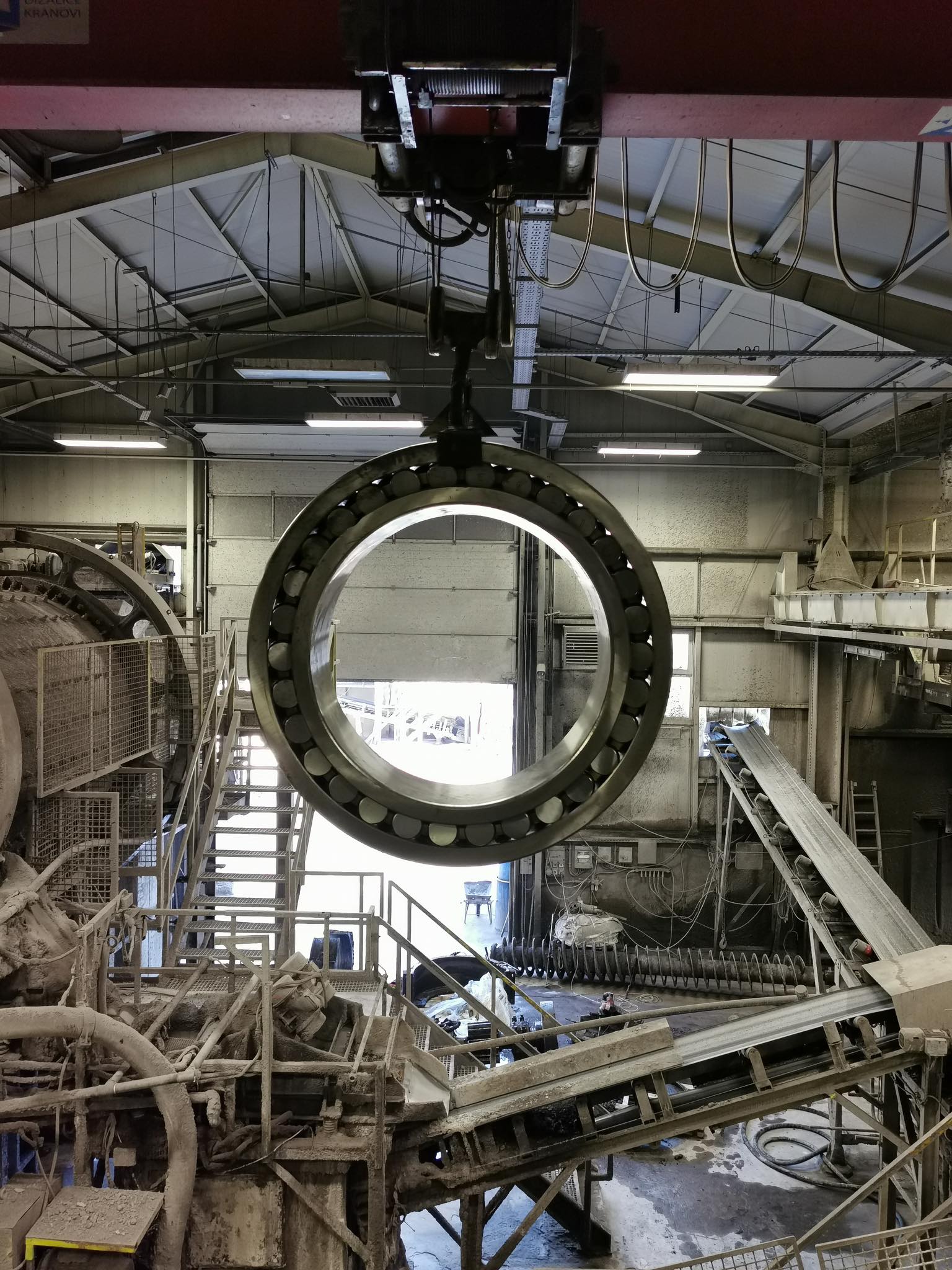

Reliable Industrial Repair

& Spare Parts Production

Our extensive experience in industrial repair and spare parts production enables us to support a diverse range of sectors, including manufacturing, automotive, energy, and utilities. By providing high-quality repairs and customized components, we help businesses maintain operational efficiency and meet the demands of a competitive market.

At Filmont, our Industrial Repair services are designed to ensure the longevity and efficiency of your machinery, minimizing downtime and maximizing productivity. We understand that industrial equipment is the backbone of your operations, and any malfunction can lead to significant disruptions and financial losses. That’s why we offer comprehensive repair solutions tailored to meet the unique needs of various industries.

Our skilled technicians are equipped with extensive knowledge and hands-on experience in repairing a wide range of machinery and equipment. From routine maintenance and inspections to complex repairs and refurbishments, we utilize advanced techniques and high-quality materials to restore your machinery to optimal performance.

At Filmont, we recognize that the availability of high-quality spare parts is crucial for maintaining the efficiency and reliability of your industrial machinery. Our Spare Parts Production services are tailored to provide you with custom and standardized components designed to meet the specific demands of your operations. With our advanced manufacturing capabilities and commitment to quality, we ensure that your equipment remains operational with minimal downtime.

Our spare parts production process begins with a thorough understanding of your requirements. We collaborate closely with our clients to identify the exact specifications needed for each component, whether it’s a custom part designed for a unique application or a standard replacement for common machinery.

At Filmont, we understand that machinery failures can occur unexpectedly, leading to significant operational disruptions and potential financial losses. That’s why our Emergency Repairs services are designed to provide rapid and effective solutions when you need them the most. Our dedicated team is committed to minimizing downtime and restoring your equipment to optimal functionality as quickly as possible.

Service work and processing of holes in the field (mechanization and industrial components)

At Filmont, we understand that reliable service is the backbone of productive operations. Our Service Work combines proactive maintenance, rapid emergency repairs, and meticulous refurbishments to keep critical equipment operating at peak performance. With a focus on precision, quality materials, and data-driven planning, we tailor maintenance strategies to your specific assets and production schedules. Our engineers diagnose issues quickly, implement durable solutions, and institute preventive measures that minimize downtime while extending equipment life. Partner with Filmont to transform maintenance from a reactive necessity into a strategic enabler of operational excellence.

We deliver durable, code-compliant joinery and fabrication for industrial equipment, structures, and infrastructure. Our certified welders bring extensive experience across materials and processes, delivering welds that resist harsh environments and heavy use. We combine rigorous quality controls, advanced techniques, and material expertise to ensure structural integrity and long service life. Whether on-site or in-shop, our welding solutions are designed to meet exact specifications, enhance safety, and support reliable operations across your facilities.

Manufacture of industrial equipment and assembly of steel structures and welded parts (we have obtained the standards EN 1090 EXC. 2 and EN ISO 3834 -2)

We provide integrated repair, maintenance, and custom component solutions that align with your manufacturing goals—from initial equipment assembly through ongoing operation. Our approach combines rigorous process control, high-quality materials, and precise workmanship to reduce downtime, extend asset life, and ensure consistent product quality. With a focus on reliability and efficiency, Filmont supports your roadmap from design optimization to sustained, high-performance production.

Empowering industries with precision repairs and custom solutions

Powering Heavy

industry

With a focus on precision, quality materials, and process optimization, we help these industries achieve consistent throughput, improved reliability, and lower total cost of ownership. Whether on-site or in-shop, Filmont delivers integrated solutions that align with your production goals and safety standards, enabling your facilities to operate at peak performance.

Installation of industrial equipment

Industrial equipment, lines, upgrading and repairs of existing equipment and dismantling work (demolition of obsolete steel industrial halls, devices and machines) on a turnkey basis

Repair and service work

Routine maintenance, emergency repairs, and extensive refurbishment of equipment to extend its lifespan and optimize performance

Manufacture of industrial equipment

We worked mostly on various containers (for production, for transport by truck, abroll and with an opening bottom), transport augers for bulk materials, bulks, bases of electric motors and reducers, industrial carts, staircases, platforms, fences

Manufacture of spare parts

According to plan or sample (machining – various components from rollers, shafts, flanges, clamps, plain bearings and plain guides, etc.)

Manufacture structures

Manufacture and assembly of steel structures and welded parts (we have obtained the standards EN 1090 EXC. 2 and EN ISO 3834 -2)

Welding services

REO, MIG/MAG and TIG – A-tested welders

Service work

Service work and processing of holes in the field (mechanization and industrial components)

Our Working

Process

Consultation & Assessment

We begin by understanding your specific requirements through in-depth consultations. Our team conducts a thorough assessment of your machinery and operational needs to identify areas for improvement and potential solutions.

Customized Solutions

Based on our assessment, we develop a customized plan that includes repair strategies, maintenance schedules, and spare parts production tailored to your operations. We prioritize quality and efficiency to ensure minimal disruption.

Implementation

Our skilled technicians execute the plan with precision and care. Whether it’s conducting repairs, manufacturing custom parts, or performing routine maintenance, we adhere to industry best practices and safety standards.

Ongoing Support

Our relationship doesn’t end with project completion. We offer ongoing support and maintenance services to keep your machinery in optimal condition and ensure long-term success.

Customers

Trusted By industry

Leaders and Innovators