Reliable Industrial Repair

& Spare Parts Production

Repairs and spare parts

High-quality repairs and custom spare parts to keep your operations running.

About Our

Company

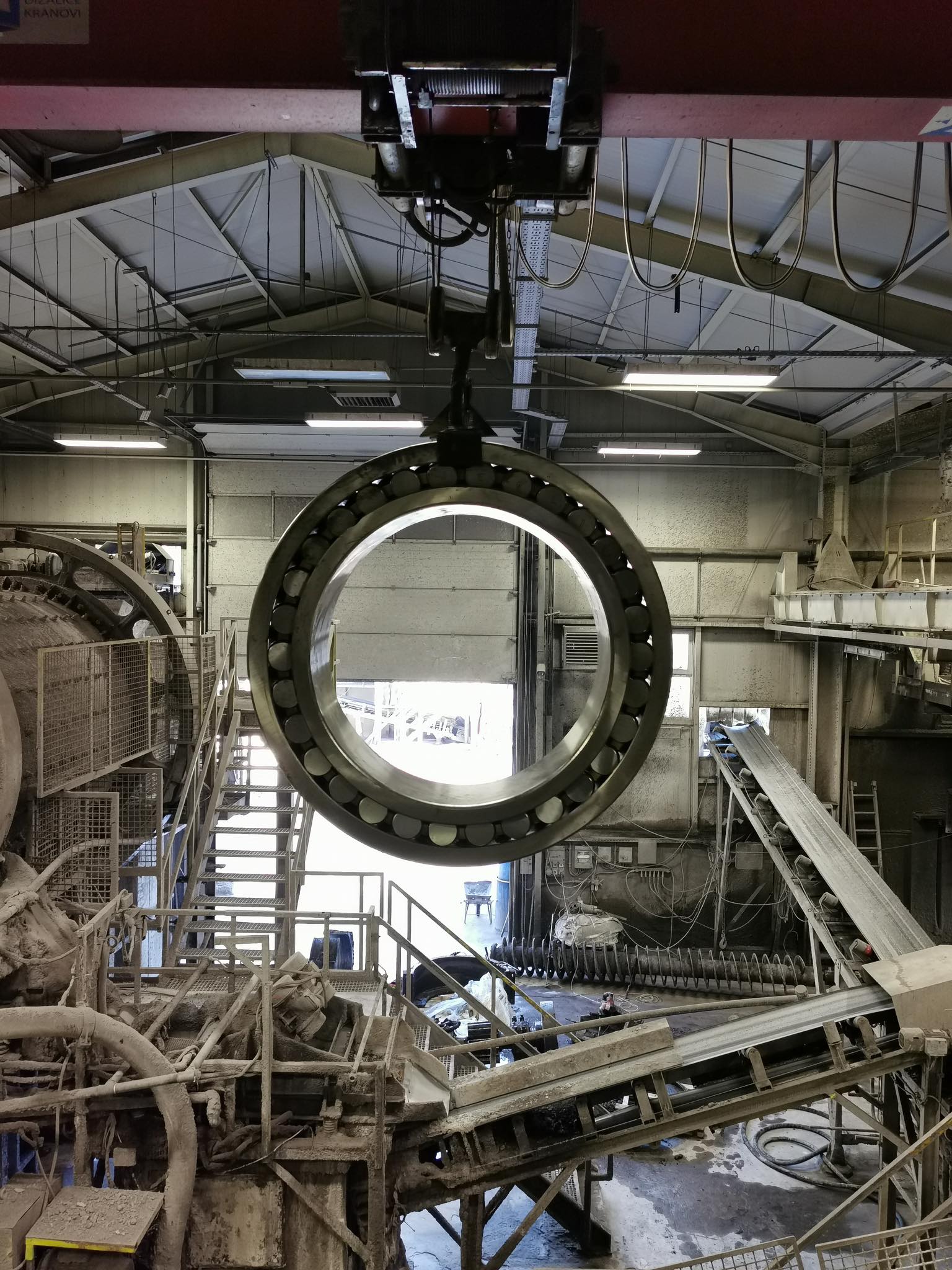

With years of experience in industrial repair and spare parts manufacturing, Filmont specializes in providing durable and precise solutions for various industries. Our expertise ensures minimal downtime and maximum efficiency.

Opportunities, delivering solutions

With years of experience in the field, we specialize in delivering high-quality services that cater to a diverse range of industries, including manufacturing, automotive, energy, and heavy machinery.

Tons Metal Extracted

Pure Metal Output

Services

Installation Repair

& Manufacture

Our extensive experience in industrial repair and spare parts production enables us to support a diverse range of sectors. By providing high-quality repairs and customized components, we help businesses maintain operational efficiency and meet the demands of a competitive market.

Discover how we can optimize your operating machines

At Filmont, we understand the critical role that efficient machinery plays in your operations. Our expert team utilizes advanced techniques and high-quality materials to enhance the performance of your industrial machines. With tailored maintenance plans and precision repairs, we minimize downtime and ensure your equipment runs at peak efficiency.

Service work and processing of holes in the field (mechanization and industrial components)

Manufacture of industrial equipment and assembly of steel structures and welded parts (we have obtained the standards EN 1090 EXC. 2 and EN ISO 3834 -2)

Empowering industries with precision repairs and custom solutions

Powering Heavy

Industry

Filmont partners with key heavy industry sectors to power safer, more efficient operations. From steel and ironworks to mineral processing, cement, paper, foundry, and wood processing, our expertise spans the full spectrum of demanding environments. We provide tailored maintenance, rapid repairs, and custom components that endure harsh conditions, reduce downtime, and extend asset life.

Steel and ironworks

Filmont supports steel and ironworks with robust maintenance, rapid repairs, and custom components designed for high-temperature, demanding environments. Our solutions focus on maximizing uptime, ensuring safety, and extending equipment life in mills, rolling lines, and finishing shops.

Mineral processing

In mineral processing, Filmont delivers proactive maintenance, precision repairs, and tailored wear parts that withstand abrasive materials and harsh conditions. We aim to improve throughput, reduce unplanned downtime, and optimize overall equipment effectiveness across crushers, grinders, and separation systems.

Cement

For cement plants, Filmont provides turnkey repair and maintenance services, alongside engineered spare parts that stand up to kiln heat and dusty environments. Our goal is to minimize downtime, maintain consistent cement quality, and extend equipment longevity.

Paper

In the paper industry, Filmont offers reliable maintenance, swift repairs, and custom components that support continuous operation of presses, dryers, and handling systems. We target improved uptime, stable production speeds, and enhanced equipment reliability.

Foundry

Foundry environments demand tough, high-temperature capabilities; we deliver rugged repairs, on-demand part fabrication, and preventive maintenance to keep furnaces, molds, and casting lines running. Our focus is reduced downtime, safer operations, and longer service life for critical foundry equipment.

Wood processing

For wood processing, Filmont provides durable maintenance and repairs, plus custom parts for sawlines, debarkers, and conveyors exposed to dust and moisture. We aim to boost throughput, minimize interruptions, and extend the life of machinery in lumber mills and wood product facilities.

With a focus on precision, quality materials, and process optimization, we help these industries achieve consistent throughput, improved reliability, and lower total cost of ownership. Whether on-site or in-shop, Filmont delivers integrated solutions that align with your production goals and safety standards, enabling your facilities to operate at peak performance.

Latest Project

Recent Success

Highlights

Recently, we successfully completed a major refurbishment of a manufacturing assembly line, which resulted in a 30% increase in operational efficiency for our client. Additionally, our team provided critical emergency repair services for an automotive production facility, reducing downtime from several days to just 24 hours. Each project reflects our dedication to delivering high-quality results tailored to our clients’ unique needs, reinforcing our reputation as a trusted partner in powering industries forward. Explore our latest achievements and see how we can help transform your operations!

Our

Working

Process

At Filmont, we believe that a transparent and efficient working process is key to delivering exceptional results.

#

reliable,

high-quality solutions

At Filmont, we believe that repair and service work is more than just maintenance; it's the art of transforming challenges into opportunities for operational excellence.

- Matic Sodja, Founder of Filmont

Consultation & Assessment

We begin by understanding your specific requirements through in-depth consultations. Our team conducts a thorough assessment of your machinery and operational needs to identify areas for improvement and potential solutions.

Customized Solutions

Based on our assessment, we develop a customized plan that includes repair strategies, maintenance schedules, and spare parts production tailored to your operations. We prioritize quality and efficiency to ensure minimal disruption.

Implementation

Our skilled technicians execute the plan with precision and care. Whether it’s conducting repairs, manufacturing custom parts, or performing routine maintenance, we adhere to industry best practices and safety standards.

Ongoing Support

Our relationship doesn’t end with project completion. We offer ongoing support and maintenance services to keep your machinery in optimal condition and ensure long-term success.

Customers

Trusted By industry

Leaders and Innovators